Modeling of turbulent premixed flames

Project participants: Senbin Yu, Micheal Bertsch, Robert-Zoltan Szasz, Xue-Song Bai

Background

Turbulent premixed flames are widely encountered in combustion devices, for example, gas turbine engines, spark-ignition engines, and cooking devices, etc. Pilot flames are frequently used to stabilize turbulent premixed combustion process under challenging conditions, for example, in gas turbine engines running at part load under lean premixed conditions, or during the startup ignition period of engine operation. In recent experiments of high speed jet premixed flames running at high Karlovitz numbers, large pilot flames have been used to enable the stabilization of the flames to the burners. It is expected that the pilot flame affects the main flame through the following mechanisms: (a) providing the heat and radicals to the reaction zone of the main flame, (b) preventing the cold ambient air from being entrained into the main flame, and (c) modifying the stretch rate of the main flame. One of the main goals of this project is thus to elucidate the effects of pilot flames on the structure and propagation of the main flame.

Project objectives and goals

The main objectives of this project are to gain improved understanding of the turbulent premixed combustion process and to develop mathematical models for the predictive simulation of turbulent premixed flames. Short-term goals include:

- Quantification of the effect of pilot flame on the structures and propagation of turbulent premixed flames at different Karlovitz (Ka) numbers

- Evaluation of transported probability density (PDF) models for large eddy simulation (LES) of turbulent premixed flames

- Development of flamelet models for LES of turbulent premixed flames considering the effect of flame stretch on flame stabilization in swirl combustors relevant to gas turbine engines

Recent results

The structure and propagation of turbulent premixed jet flames exhibit distinct characteristics at different Karlovitz numbers, with and without pilot flame stabilization. Two-dimensional detailed numerical simulations were performed for the laminar premixed flame, while 3D LES was carried out for the high Ka number turbulent premixed flames.

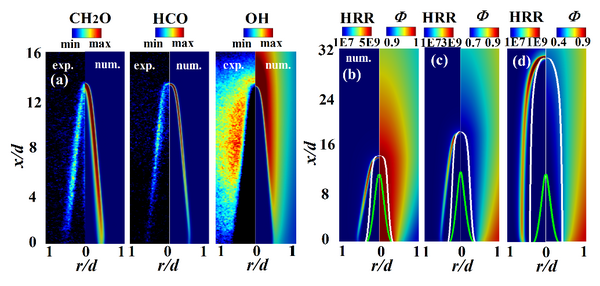

For laminar premixed flames, it is found that the reaction zone of the piloted jet flame is in the mixing layer of the main jet and the hot coflow from the pilot flame, see Fig. 1. The equivalence ratio in the reaction zone can be significantly higher than that in the fuel/air mixture of the main flame, especially for the main flame that has a much lower equivalence ratio than that of the pilot flame. This explains the sustained ultra fuel-lean main flame (with an equivalence ratio of 0.4, which is below the lean flammability limit) by the pilot flame with an equivalence ratio of 0.9. The burning velocity of the main flame is insensitive to the hot gas composition from the pilot flame, indicating that the heat transfer from the pilot flame to the main flame has a more significant impact on the main flame than the transfer of the radicals and combustion intermediates (such as CO and H2) from the pilot flame to the main flame.

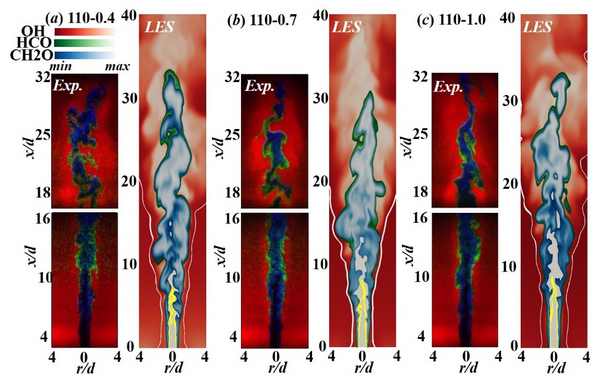

For highly turbulent flames, the preheat and reaction zone are located at the mixing layer, the equivalence ratio of which is between Φjet and Φpilot. The reaction zone is more influenced by the pilot flame at higher strain rate closer to the burner exit, or at a higher jet velocity. It is found that a higher main jet velocity causes a larger heat loss, pushes the flame outwards, thus more diluted by the pilot flame. The normalized flame thickness, δ/δ0, is dominated by the strong strain rate in the near field. In the downstream region, δ/δ0 increases due to the higher turbulent diffusivity, flame merging in the cone-shaped flame tip region, and the lower Tpilot caused by the entrainment of the cold ambient air near the flame tip. Those cases with a larger flame thickness, as well as flame volume, have much smaller reaction rates. It is also revealed that the temperature of the pilot plays a dominant role in affecting the flame thickness.

Sample Publications:

- Yu S, Bai X S, Zhou B, et al. Numerical Studies of the Pilot Flame Effect on a Piloted Jet Flame. Combustion Science and Technology, 2019: 1-14.

- Yu S, X Liu, Bai X S, et al. Structure and propagation of high Karlovitz number turbulent premixed jet flames stabilized in a large co-flow pilot flame. Submitted to Symposium.

Funding agency:

VR, STEM through CECOST